double like !! ^^^ man this progress is looking

No check valves. No metering valves. It doesn’t look like PVC. it’s for sure not sch 80. I think it’d function, but not well, if you want any control over your mix.

I’m not sure what the colors mean but in response to your question, it’s most common to talk about the strength of the mix as the percentage of SH that is actually landing on the surface if you are primarily soft washing houses. Other than “50/50” and “straight 12.5%” you will rarely hear pressure/soft washers refer to a mix as a ratio. Usually they will say something like I hit it with 6% or I used 2gl Sh to 3 gl water to mean the before the downstream injector mix.

On the other hand It’s been my experience that most roof washers will generally say they used a 64% mix rather than saying 8% or a 35% mix rather than saying 4.3% for example. The difference is because the way the chemical is applied is so different if one is using a downstream injector vs a chemical sprayer.

Hope that answers your question. I would leave the chart with both the mix ratio and the SH strength.

I see. I can’t speak to downstreaming. I’m specifically talking about a softwash / 12V diaphragm pump application system here. But yeah, kind of confusing, especially if people refer to it two different ways. I appreciate the advice.

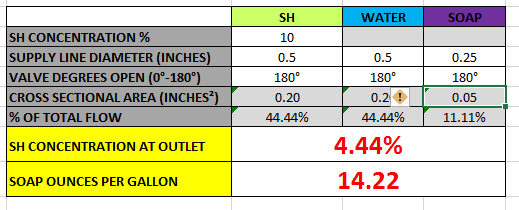

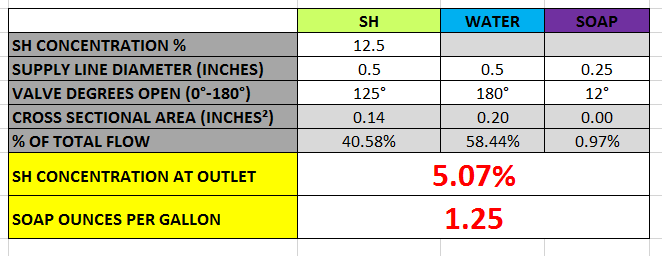

Can you give me your feedback on this tool I just created in Excel? I think it’s pretty cool, and anyone else’s thoughts are more than welcome!

Basically I put in all the formulas needed for a 3 valve softwash metering system. There are 7 variables you can adjust, based on your system or the system you want to try.

- SH concentration % (8, 10, 12.5)

- SH supply line diameter

- Water supply line diameter

- Soap supply line diameter

- SH valve degrees open

- Water valve degrees open

- Soap valve degrees open

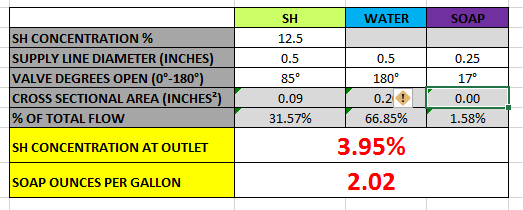

It has 2 outputs, SH concentration of the mix (shown as %) and soap in the mix (shown in oz/gal). It’s pretty cool in my opinion. Because of all the variable, the system will pull more or less soap in, depending on how far you open the SH valve, and it all changes depending on what size supply lines you have, and of course what SH strength you are using.

So if someone wanted to calculate their softwash mixing ratios with 10% SH instead of 12.5, they’d just change the value. Or if they wanted to know how much soap you’ll pull in to your mix if you have a 4% SH strength, you can add in the numbers and get your answer. You can see how far to open each valve to get the desired mix.

I want to take this a bit further and have it reverse calculate, meaning you type in the desired outcome and it tells you how far to open each valve to achieve that SH strength and soap content. That’s a bit more difficult though lol.

Thoughts?

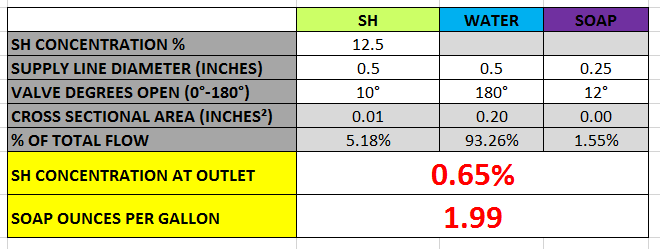

Here is an example where it might be helpful.

This is your softwash setup: 12.5% SH, 1/2" SH supply line, 1/2" water supply line, and 1/4" soap supply line.

You wash the house with a .65% mix and 2 oz/gal of elemonator. To get that, the SH valve is at 10° open and the soap valve is 12° open. But they their roof is filthy, so you need to go up to 5% mix and you still want 2 oz/gal of soap. So you just up your SH valve to 125°. But since the ratios of cross sectional area has changed, you are only going to be applying 1.25 oz/gal of soap in your mix.

I mean, it’s probably not super critical obviously, but with 3 variable valves, the ratios aren’t exactly linear. This is exaggerated even more with larger SH and water supply lines.

I guess I’m not even sure if anyone cares if they are getting 2 oz/gal or 1.25 oz/gal, and maybe it doesn’t make a huge difference. But at least here is the math that shows it.

I think a four-way system has utility for the option to pull acid in (for two-stepping oxidized siding).

Do many people use their softwash system for rinsing also? @Racer, do you you rinse with water only sometimes after you softwash? Is this the situation where you experience distance loss?

I only use my soft wash system for roofs, but if I ever would need it for a brick wall or something I’d use the pressure washer, much higher gmp volume to flush out all the nasties

Thank you for your input!

Some do. I usually just use my pw unless real little job and I don’t feel like unrolling it.(pw)

But a lot of people running boosters now.

I dont usually rinse with the 12V, but often do with the booster. Also with the pressure washer, of course.

Thanks for the feedback guys. I’m just trying to sort out the flow problems a bit. My understanding is that with water and SH valves open, the pumps get more distance. Distance decreases as valves are closed. This could be a situation where someone is rinsing with their 12V pump or using a really weak mix (SH valve not opened much at all). I’m looking at ways to extend pump life and get better performance in general even when using a weaker mix or when (if ever) rinsing with the 12V. Higher flow only makes life easier on the pump and really can’t be overdone, especially since we are talking suction side anyway. But restricted flow could negatively effect a pump. Imagine drinking your soda (coke, pop, whatever) through a small mixing straw vs through a large straw or smoothie straw. It’s WAY easier to suck in your drink with the larger straw. Same concept with the pump. So how to do it best…larger valves? More valves? Both? That’s what I’m trying to sort out.

would this change with the 3/4 ball valves?

Ratios will remain the same as long as the SH and water valves are the the same size as each other. The values change a little bit as you start opening up the small soap valves, but it’s not a huge difference. For our purposes, I’d probably consider it negligible.

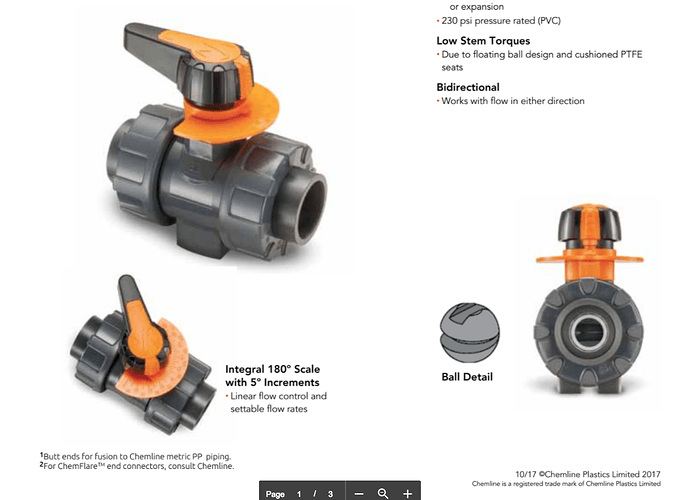

New valve design release. What do you guys think? I can get this metering valve in 1/2", 3/4", and 1". Has mounting plate with bolt holes, newer handle design, and a scale that you don’t have to read with your head sideways or upside down.

any luck finding 3/4 high flow hastelloy check valves?

any luck finding 3/4 hastelloy valves? I’ve spent too much time today

looking and didnt find any high flow valves

Thank you,

Lee Rivenbark

*Owner * | Pro Pressure Washing

*Office: 910-270-7767 * *| *Fax: 888-998-7767 | **

http://www.propressurewashing.com/

Email: lee@propressurewashing.com lee@propressurewashing.com

- The information contained in this transmission (including any attached

files) is CONFIDENTIAL and is intended only for the person(s) named above.

If you received this transmission in error, please delete it from your

system and notify us immediately. If you are not an intended recipient,

please note that any use or dissemination of the information contained in

this transmission (including any attached files) and the copying, printing,

or re-transmission of that information is strictly prohibited. You can

notify us by return e-mail. Thank you.*

Yes, I have 3/4" hastelloy spring valves picked out. I just ordered some 1/2" today actually. 3 week lead time. I could get 3/4" too though. However, I think the diaphragm check valve is a better option.

Amazing work so far @jzbreeland.

You mentioned that it might be better to do a diaphram check valve instead of the ones with the Hastelloy Springs. Something like this? 3/4" NPT PVC CKM Diaphragm Check Valve with EPDM Diaphragm | U.S. Plastic Corp.

Could you link the 3/4inch Hastelloy Check Valves you said you ordered?

Do you think its worth doing 3/4inch Metering Ball Valves for “water” and “SH” on something like the THE FATBOY BANDIT ROOF CLEANING SYSTEM from pressuretek.com instead of building the specs of the “proportioner” ? Which we know is 1/2inch.

keep up the great work… interested in seeing if you come up with a manifold for this as well.