Have you put a gauge on it to see what psi you are getting? Are you sure motor is spinning at 3600

Yeah, and I checked the motor with a tach, it sits around 3450. Im wondering if there’s some kind of gearing that’s slowing the shaft down within the motor. I don’t have the time to take it apart; may just pull the trigger and get a Honda.

Yes, verified with a tach

I didn’t check PSI, I know its low though, id guess around 1000-1500

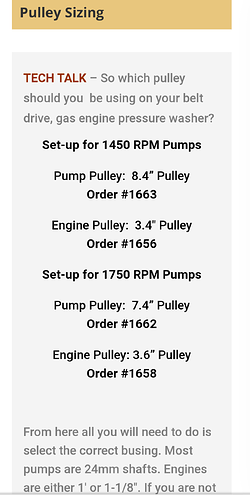

You need a 3.25 pully on the motor

Weren’t you just saying they were backwards? 3.25 would give me a 1.8-1 ratio; which would run the pump at 2000rpms and kill it…

I didn’t say they were on backwards I asked to make sure.

Sorry about that, misread it.

I would at least try a 3. I’m assuming you did the test without the ball valve.

Correct, no valve. Based on the output, it seems like it’d need a 6" to get it to where it needs to be. I’m at a complete loss. I could throw a 3" on there, but 1/4" bigger is only going to spin it about 100 rpm faster. Agree?

Thats a 2.47-1 ratio. That would slow it down even more.

Put the 3 on it if you have one. I still think you need a 3.25 but that’s just me

To OP

Sorry, I didn’t read the entire thread.

But is the pump a direct drive pump? And you just put a pulley on it?

If so, That’s your problem… The inner crank in the pump isn’t geared to be pulleyed. Belt drive pumps have a different inner crank

I dont think from his pictures it’s a DD pump

Unloader set properly?

Its a belt driven pump. The motor was from a direct drive machine.

Yes, I dialed it in.

Do you have a sight glass on that pump

Yes, plenty of fresh oil