That puts you at about 2500 psi. Probably a little less after your 200’ of hose or whatever length you have.

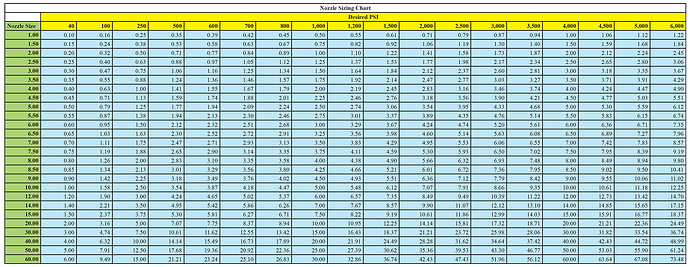

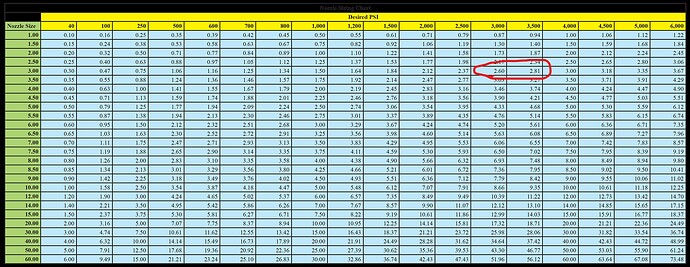

Take a look at the nozzle chart. Keep in mind that you have a 5.5 gpm machine. Let’s stick with one single nozzle on the end of your gun for now. Let’s say you want to use a nozzle that puts out 1200 psi. Look at the top row and follow it to the right until you see 1200 psi. Now follow it down to find 5.5 gpm. (The closet to 5.5 is 5.48). Now follow it to your left to get your nozzle size. So, a #10 nozzle will get you right around 1200 psi.

Let’s say you want a nozzle for you gun putting out 3000 psi. Find 3000 psi up top, follow it down to get to as close to 5.5 gpm as you can (5.63 gpm), now follow it to the left and you find 6.50 nozzle.

Now take the first example but for a surface cleaner with two nozzles. Let’s say you want that same 1200 psi. The surface cleaner has two nozzles so we want 2.75 gpm per nozzle (half of your pump’s 5.5 gpm). Go to 1200 psi in the yellow. Follow it down to find 2.75 or as close to that as you can get. (There’s a 2.74) Now follow that to the left and we get a #5 nozzle. So, two #5 nozzles put out 5.48 gpm and 1200 psi. I know you’ll likely never use 1200 psi for a sc but it’s just an example.

The main thing to remember is your 5.5 gpm. You always want the nozzle or nozzles putting out at the 5.5 gpm so that’s the main thing you’re looking for on the nozzle chart.

Now let’s say you wanted to get around 3000 psi on your surface cleaner. Follow the psi over to 3000 psi. Go down to find 2.75 gpm (half of 5.5). 2.60 is about the closest to 2.75 gpm. If you look at 3500 psi and follow it down to that same row you’ll see a 2.81 gpm. Remember, you’re looking for 2.75 gpm which falls in between 2.60 and 2.81 gpm. Follow that to the left and you get a #3 nozzle. So, if using a #3 you’ll be getting right around 3250 psi. Probably a little less due to hose length and fittings.

The psi of your machine (5000 psi) doesn’t really mean much when looking at a nozzle chart so just forget about it. The only time it matters is if you want to actually put a nozzle on that reaches a certain psi. If you only have a 2500 psi pump you won’t be able to use a 3000 psi nozzle. With your 5000 psi you won’t ever have a problem of not being able to reach a certain psi.

The first two numbers, 25 in this case, is just the degree of the spray. 25 degrees is what’s used for surface cleaners. I normally use a 40 or even 65 degree nozzle when doing deck boards.

I didn’t answer your question on your whisper wash but hopefully helped you understand a nozzle chart a little better. Just ask if you’re still confused. You’ll get the hang of it though. It’ll all of the sudden just click.