I tried to get a compression to 1/4 npt adapter to use the GP downstream and that was a no go. So instead, I took my 2.1 injector apart and drilled the orifice out to 2.3mm.

Still no luck…

25085 nozzle:

3000psi not spraying

2000psi bypass closed - won’t pull soap

1800psi bypass open

black soap nozzle:

1000psi bypass closed - pulled soap

0psi bypass open

Not sure where to go with it now

You’re going in the wrong direction here. You need a smaller orifice to pull soap at higher pressures.

Call the doug rucker store and see if they’ll sell you just the adapter fitting.

Won’t do me any good now. both of my gp downstreams are 2.3

Looks like you’re going to need a new injector, then. I would still try and get ahold of one of those adapters, as the GP’s are sort of ubiquitous.

Can you pm what downstream orifice size you’re using?

I picked up an 8.5 nozzle since the shop didn’t have an 8.

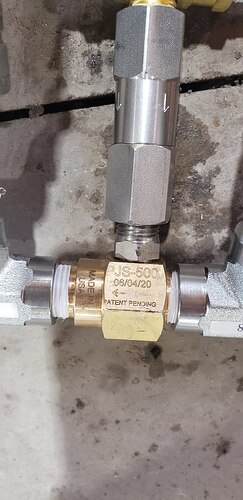

I welded the orifice shut and redrilled to 1.8mm. I also moved the pressure gauge to the other side of everything to see application pressure not line pressure.

With the 8.5 nozzle I’ll see 1600 psi in bypass and 1500 with it closed and it won’t pull soap.

With the 25060 nozzle it came with Im seeing 2500 psi in bypass and 2000 trying to pull soap.

It will still pull hard with the black soap nozzle

My math above shows you should use a 1.7 orifice.

1.8 is somewhere around a 7.75 orifice. I don’t think it’s creatig enough of a pressure differential to pull with a 8.5 nozzle.

Wouldn’t a 1.7 choke the machine? How could it flow 5.5 gpm when a 1.8 is only rated for 2-3gpm

1.7 is a 7.0 orifice. It will generate ~2500 psi @ 5.5 gpm.

Yeah thats what the chart shows, but not what I’m seeing. My machine bypasses (not pulling the trigger) at 3000psi. When I have a 6.0 nozzle in it with 100ft of 3/8 hose Im seeing 2500 psi with the handle bypass open and 2000psi through the 1.8 downstream.

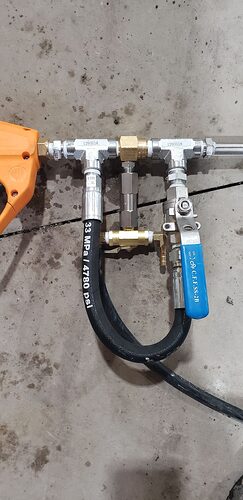

Where’d you have the pressure gauge installed when taking those measurements?

The first set of pressures I posted the other day it was between the wand and the hose.

The pressures I posted yesterday it was between the downstream and the end of the nozzle

Ok, I would run your test again with the gauge between the hose and gun.

It sounds like you’ve got a 500psi pressure drop through the injector, which is only 20% of your max pressure of 2500 psi. But at this point, the math and physics of it all starts to screw with my brain a bit. That’s why I’m curious to see what the pressure is like before the gun, with bypass both open and closed.

Hey guys, I need some help. I came across this because I to built my own 2 step gun and cannot get it to draw soap. It has pretty much the same set up as your gun. It has a 25085 tip and no SOAP!!! HELP PLS

Sorry, I guess I should have added that I’m running at 3000psi 5.6gpm. Any help would be much appreciated.