I have a 10.5 gpm pump run by a 35 hp vanguard with a Greenspring unloader that is who knows how old but I’m sure more than 10 years old. Anyways yesterday I was getting ready to surface clean a driveway I cleaned just last year so it wasn’t super dirty. I have 1/2" hose for when I have a big drive or its dirtier but for this I was going to use my 150’ 3/8" hose. I hook it up ball valve shut and the belt starts squealing, no big deal I go to tighten the belt some nuts were loose so I figured that was the problem. I go to start it back again and it still doesn’t seem right so I shut it off quick again and try again with just my 1/2" whip line and a ball valve starting closed. Starts up fine and can see water bypassing and is cycling good turning the ball valve open and closed. I try with the 3/8" doesn’t seem right again and boom, the hose pops. Only 140 hours for Goodyear Neptune hose in near perfect condition no wear near the leak spot. I finished the job fine with the 100’ 1/2" hose and a 50’ 3/8" hose but it just seems weird to me. Would anyone have insight about that?

I’m going to go ahead and change the unloader because I have a spare for it and its old but really I’m just butthurt about my hose popping hahah

Sounds like you answered your own question. Unloader is kaput.

I just find it weird that it worked fine with the half inch whip and then going to the 3/8 it didnt work then back to 100’ 1/2 it worked just fine . But yeah hopefully that’ll fix it, itll at least give me piece of mind changing it out

The unloader had to be set for either 3/8 or 1/2. There isn’t a universal setting for both

not sure if serious, or just messing ^

not sure if serious, or just messing ^

I was going to say the same thing but didnt want the smoke if serious.

I thought during the unloader setting process that I’ll use my highest pressure rated tip on a short whip line and turn the unloader until there’s only a dribble coming out. Once it’s set the pump will be able to pump out its maximum psi with both 1/2" and 3/8" hose but with 3/8" hose having less psi at the end of the hose due to friction lose. So no matter what the pump will be able to push out the same numbers just with 3/8" hose I’ll have less psi and probably some water bypassing. Is that not how it would go or you saying it’s worse on the unloader to do that? Ive used both hoses many times without adjustments needed successfully but I could understand if you told me it was bad on my unloader to do so. Now im curious

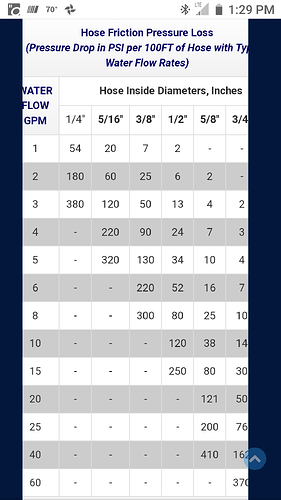

If you set max psi on the 1/2, when you use the 3/8 it will be a higher psi. Not sure how much, but remember you lose psi when you move to bigger amd longer hose. Any imcrease in capacity lowers psi. If I used a 200ft 3/8 hose and went down to 100ft, there would be a increase in psi. Theres a chart I think @racer posted once about psi loss and hose, could have been @dperez .

Could have been a combo of things.

There’s the chart. I do agree that it couldve been a combination of things obviously the hose had too much pressure or it wouldn’t have burst. It’s one wire hose I think rated for 3000 psi so maybe the reoccurring 3600 psi when the machine goes over to bypass wasnt good for it either

That was my attempt at humor