That’s crazy! Glad you are ok!

Dang man, I hate to hear that and hate to see the damage to all your work. However, glad your ok and no one was hurt.

Brodie, I wish I would have said something because I was wondering about all that equipment in the back of the trailer. I just went through this with my trailer is why I was wondering. I had 3, 15 gallon tanks in the front of my trailer and as long as they were full the trailer pulled fine. One day last week we used almost all 45 gallons of chemicals and on the way back to the shop I got that terrifying wobble!

Somehow I had mounted all my equipment in a configuration that made the trailer almost perfectly balanced, and needed the weight of the chemicals for tongue weight. I didn’t want to rely on having to have full tanks to have it pull right, so last week I had a trailer repair shop just move the axle back to give me more tongue weight and now it pulls like a dream. I’m very happy to hear you’re ok!

Thanks guys. I slept in. Took my dogs for a walk. Got caught up on some admin stuff that’s been on my mind and I feel like a new man.

Here’s what I’m thinking:

Get the tank water tight.

I think I need to shore up the legs of the machine racks since they spread a little in the truck and trailer tornado. (Super not good, potentially, with all the vibration from running machines)

Sketch out about how much everything behind the axles weighs and fill a couple 55 gallon drums full and strap them to the front wall.

Put another 110 gallons in the tote.

That way I’ve got 1600# at the axle and before. But that means, @Trp5925 needs to have at least 1000 lbs of gear and soap and whatever before the axle. Right?

@Infinity your post about 20% on the tongue… so he could safely get by with 240# if the rest of the LOAD weighs 1200#? Or 20% of the entire trailer weight?

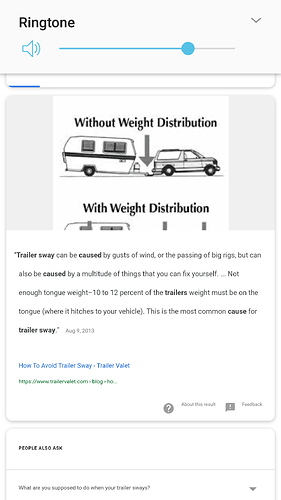

20% Might even be a little high. I’ve always. Heard/used 12 to 15%. Either way, long term solution is moving axle once he decides the equipment is whete he wants to keep it.

Isn’t the trailer dual axle? I’ll also be hauling it with a little bigger truck than you are as well (don’t crucify me I know bigger truck isn’t the solution for this issue) just thinking that would play a small role in helping out.

I believe it goes this way.

Do not exceed 10% of tongue weight.

60% of total weight should be on front of trailer axle.

Thats how i do it

Doesn’t matter how big the truck is if trailer isn’t balanced. Barrel of water in front isn’t legitimate option. Move the axle or move the equipment. I know you need the trailer i wouldn’t pull it across the street like it is now. Not really your fault or Broadies. Neither one of y’all have built a trailer set up of this magnitude before. It will only get worse when you add hoses, ladders etc. Moving axle is simplest solution. The risk is not worth the gain. Just my thoughts

What causes the dangerous wobble is a light back end of vehicle. Not enough tongue weight on trailer causes the weight to pick up on ass end of truck causing it to be light. My thoughts are it’s a lot easier to pull the weight off of his Toyota than a f-450. By all means it would definitely be better safe than sorry and just balance the trailer out

You’re not correct on what causes sway but it sounds like you are going to fix it so it doesn’t matter. I’ve built a lot of trailers. I have one with sliding axles for weigjt distribution of whatever I’m pulling. Tongue weight is key. Bigger truck means nothing if weight is wrong.

What if we did this? What if I get it tightened up over the next couple days and we do some research on having the trailer shipped, you can load it out with your equipment, balance the weight, and I’ll come down next week to work with you for a couple days and tighten anything that’s inevitably going to loosen up in transit or over a few hours of abuse and just generally work out any other bugs?

My dad, who drove tractor trailers for 37 years, seems to think the brakes locked up and should be checked, but also thinks but I don’t own a truck big enough to haul it. F2 50 included.

Like your SC rack

If you’ll get everything scooted towards the front of the trailer to help fix the issue at hand I’ll come pick it up this weekend.

The trailer needs to be taken to a weigh station and get weighed. Truck stop, grain silo, whatever. Then, after determining the weight of the trailer, add enough weight to the front to have 10-15% of that total on the tongue and you could tow it with whatever you want.

I mentioned 10% in my post, not 20. But I can see how it would have been confusing with the examples I posted. I changed the values to make it more straightforward for future readers

And yes, 10% of the gross weight of the loaded trailer.

In my opinion, no liquid/variable load should be relied upon to balance a trailer. Liquid loads should be above and just slightly (10%) forward of the axle, so filling or emptying the tank(s) doesn’t alter the balance.

When a correctly positioned tank fills up, it will increase the gross weight of the trailer, while increasing the tongue weight in proportion to the 10% rule. That’s the ideal setup, imho.

I can take it to my metal scrapper to have it weighed. It’s 20’ long from tongue to tail with 2- 5200 lb axles.

The two reel racks weigh probably 100 lbs conservatively. 6 reels. 40 lbs, 4 pressure hoses. I’m gonna reel on my old contractor hoses to the other two so lets say, 80 x 5

the two machine racks are probably 50 lbs/each

2 small machines 70 lbs each

Big machine 180 lbs with oils

IBC tote and plumbing 100 lbs

5 gallons of fuel in the tank = 50 lbs

so 200

+240

+400

+100

+140

+180

+50

+10%

= so roughly 1250 lbs I’d say over the axles and behind it.